syeda amna

Full Member level 4

Hi

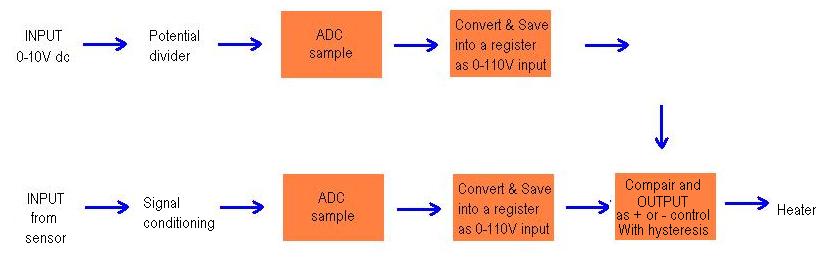

I want to design a controlled heating system with following specifications:

Input 0-10V

Output 0-110V

For increase in 1 degree temperature, will decrease the output upto 3V.

So anyone can guide me how i start working on this project. Is MATLAB will easy for doing this type of project. and what about hardware part? Please help me.

I want to design a controlled heating system with following specifications:

Input 0-10V

Output 0-110V

For increase in 1 degree temperature, will decrease the output upto 3V.

So anyone can guide me how i start working on this project. Is MATLAB will easy for doing this type of project. and what about hardware part? Please help me.