Aussie_Burger_The_Works

Newbie level 4

Hello, I have been trying to improve my battery life on a project that flashes 12V led strip. My idea was to turn the strip on and off rapidly >50hz so the flashing would not be noticeable but I could effectively halve my current consumption leading to greater battery life.

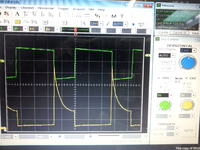

My circuit is run off a PIC micro (12F683) switching a MOSFET (P16NF06) however once I have wired the circuit up I get the following waveforms on the CRO. At the moment I am driving the MOSFET with a square wave out of my signal generator (~10v p-p).

The green waveform is at the gate to the MOSFET and the Yellow is at the Drain.

Thanks in advance

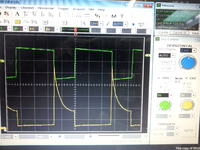

My circuit is run off a PIC micro (12F683) switching a MOSFET (P16NF06) however once I have wired the circuit up I get the following waveforms on the CRO. At the moment I am driving the MOSFET with a square wave out of my signal generator (~10v p-p).

The green waveform is at the gate to the MOSFET and the Yellow is at the Drain.

Thanks in advance