beardolphinariesg

Newbie level 2

Hi all, I have been using HFSS for about 2 months. And here I met some problem with inductor design. Did anyone meet the similar problems?

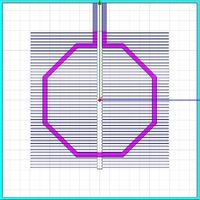

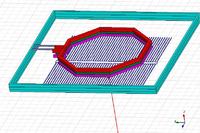

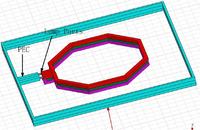

It is a octagonal symmetric inductor in Metal 6 (CMOS technology), with lumped ports: P1 and P2 as two inputs closed to each other. There is also a guard ring on Metal 1, which is also connected to silicon substrate.

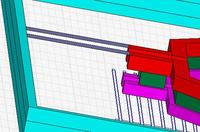

If P1&P2 are placed against Metal 1 guard ring directly, the simulation results (S11, or extracted L,Q etc.) looks OK.

If P1&P2 are against a small piece of PEC, and another port (P3) drives the guard ring against the same PEC, then the S11 changes a lot (e.g. more than half lower self resonating frequency).

Just wondering if anyone have seen this before? Thanks a lot.

It is a octagonal symmetric inductor in Metal 6 (CMOS technology), with lumped ports: P1 and P2 as two inputs closed to each other. There is also a guard ring on Metal 1, which is also connected to silicon substrate.

If P1&P2 are placed against Metal 1 guard ring directly, the simulation results (S11, or extracted L,Q etc.) looks OK.

If P1&P2 are against a small piece of PEC, and another port (P3) drives the guard ring against the same PEC, then the S11 changes a lot (e.g. more than half lower self resonating frequency).

Just wondering if anyone have seen this before? Thanks a lot.